Every hydraulic system ever designed is affected by a simple “four letter word” – HEAT

Where there is a “Pressure Drop”, there is heat.

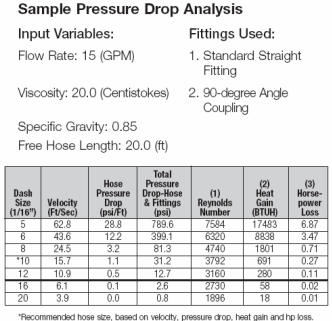

Anytime fluid flows from an area of high pressure to an area of lower pressure without producing mechanical work (Pressure Drop), heat is generated. Friction, type and temperature of fluid, length and size of hose assembly, type of couplings and adapters, and flow rate are all examples of things that can influence the amount of pressure drop. Conducting a Pressure Drop Analysis will determine the amount of pressure drop in the system. One simple solution is to upsize the components and reduce the bends in the plumbing. If radical bends are unavoidable, increasing the size of the hoses and fittings will increase the flow capacity dramatically. Example: 10 GPM through #10 SAE hydraulic hose flows at a velocity of 10 fps, while the same 10 GPM flows at 7.5 fps through #12 SAE hose. This method will decrease the heat load by a 25% decrease in flow restriction, resulting in an increase of efficiency of the hydraulic system!

Increasing heat dissipation is another technique used to cool an overheating hydraulic system. In order to achieve stable oil temperature, a hydraulic system’s capacity to dissipate heat must EXCEED its inherent heat load.