2 Common Mistakes NOT to make with your Hydraulics

2 common mistakes NOT to make with your hydraulics

Topics: Fluid Power Industry, Troubleshooting, Oil Maintenance

Because we care about your stress – timeout for oil

The most common problem I see when I visit customers with struggling equipment is in the oil. Just like the oil in your car, hydraulic oil is absolutely critical for your system to run properly. I often share four easy things you can do to improve the life of your equipment & save yourself a lot of stress.

Topics: Fluid Power Industry, Hydraulic Oil

Do you ever look down at your morning bacon and think, where did this come from? Of course it came from a pig or some other sort of animal that provides bacon, but what about the process it went through to get through to your table?

Hydraquip proudly provides the expertise that helps get the bacon from the farm to your table. From the entire fluid power circuit, custom subassemblies to innovative products,

Topics: Fluid Power Industry

As you are being pushed through the hallway of a hospital you think to yourself, what happened, why am I here? You feel nothing but throbbing pain in your arms and wish you could have done things differently. This is what happens when you are put in a dangerous situation at work. Unfor

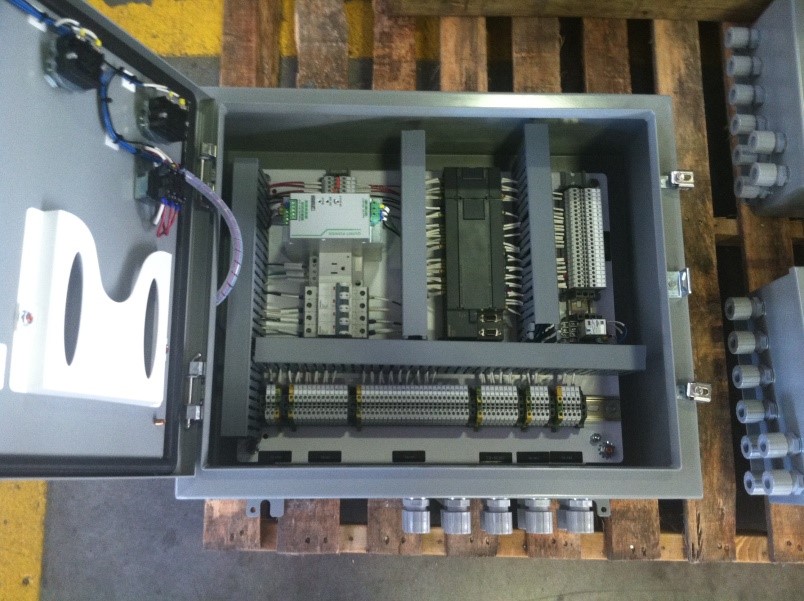

Topics: electro-hydraulic, Control Systems

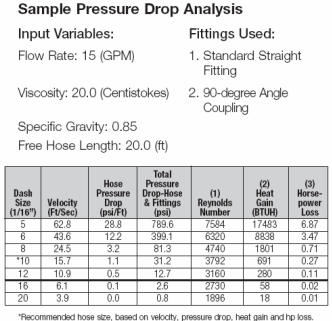

Every hydraulic system ever designed is affected by a simple “four letter word” – HEAT

Where there is a “Pressure Drop”, there is heat.

Anytime fluid flows from an area of high pressure to an area of lower pressure without producing mechanical work (Pressure Drop), heat is generated. Friction, type and temperature of fluid, length and size of hose assembly, type of couplings and adapters, and flow rate are all examples of things that can influence the amount of pressure drop. Conducting a Pressure Drop Analysis will determine the amount of pressure drop in the system. One simple solution is to upsize the components and reduce the bends in the plumbing. If radical bends are unavoidable, increasing the size of the hoses and fittings will increase the flow capacity dramatically. Example: 10 GPM through #10 SAE hydraulic hose flows at a velocity of 10 fps, while the same 10 GPM flows at 7.5 fps through #12 SAE hose. This method will decrease the heat load by a 25% decrease in flow restriction, resulting in an increase of efficiency of the hydraulic system!

Increasing heat dissipation is another technique used to cool an overheating hydraulic system. In order to achieve stable oil temperature, a hydraulic system’s capacity to dissipate heat must EXCEED its inherent heat load.

Topics: Fluid Power Industry, How To

World’s premier system integrator for Danfoss PLUS+1™ GUIDE

Our electro-hydraulic controls partner, Elite Controls, Inc. provides robust, user-friendly control systems designed to enhance the performance of equipment, improve efficiency of operations and reduce total cost of ownership.

Topics: Danfoss, OEMs, software development, electro-hydraulic

Filter Systems allow you to remove contamination and/or water quickly, conveniently and economically. Watch our video to see the features & benefits of filter carts first hand!

Topics: Fluid Power Industry, Schroeder, Filter Carts

How to Set Max Flow Rate for a Danfoss Series 90 Pump

Topics: Fluid Power Industry, Service and Repair, Danfoss

As a student you often hear your peers moan and groan saying things like, “I’ll never use this in the real world.” While this may be true for the particular job that they take after graduation, in the world of hydraulics you better take good notes. Hydraulics is a fascinating field of study, along with a very technical one.

Looking Back…

While working with some of the more complicated systems I often found myself referring to materials from early on in my collegiate career. Often times it was with topics that I, along with many others, had fallen into the “I’ll never use this” trap.

My advice to my freshman self is

Topics: Internship, Fluid Power Industry

Topics: Fluid Power Industry